Rotative & double-flap valves

The “double flap” valves

The “double flap” valves

Device based on a casing with 2 flaps acted alternately to ensure an airlock isolation

The ratary valves “premium” series

Rotary valves for basic applications

The SAS rotary valve

Rotary valve is designed for small depressions isolation or dosing purpose

The “self-cleaning” rotary valve

This valve is specifically designed for sticky products purpose, and is equipped with synchronized additional cleaning rotor

Rotary valves speeds:

| Flow rate max | Rate schedule (m3/H) | Installed power | |||

| Type / Diameter | by turn, dm3 | At 20 T/m | weigth | Isolation | Extraction |

| 200 | 4,5 | 5,4 | 70 | 0,75 | 0,75 |

| 250 | 7,9 | 9,5 | 130 | 0,75 | 1,1 |

| 315 | 15,83 | 19 | 155 | 1,1 | 1,5 |

| 400 | 33,33 | 40 | 300 | 1,1 | 2,2 |

| 500 | 67,5 | 81 | 550 | 1,5 | 3 |

| 630 | 135 | 162 | 830 | 1,8 | 4 |

| 800 | 280 | 336 | 1500 | 2,2 | 5,5 |

Double-flaps valve :

| TYPE | Flow m3/H | Power | Weight |

| 200 | 3,8 | 0,55 Kw | 200 |

| 250 | 6,8 | 0,55 Kw | 232 |

| 315 | 13 | 0,55 Kw | 295 |

| 400 | 24 | 0,75 Kw | 375 |

| 400 SR | 40 | 1,5 Kw | 430 |

| 500 | 41 | 1,5 Kw | 460 |

Technical data sheet :

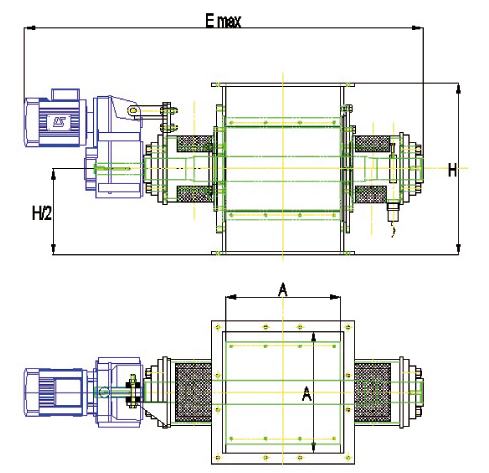

Rotary valves – dimensions :

| Diameter (mm) | A | E | H |

| 160 | 180 | 870 | 250 |

| 200 | 220 | 910 | 315 |

| 250 | 270 | 975 | 400 |

| 315 | 336 | 1180 | 500 |

| 400 | 420 | 1315 | 630 |

| 500 | 524 | 1450 | 800 |

| 630 | 660 | 1725 | 900 |

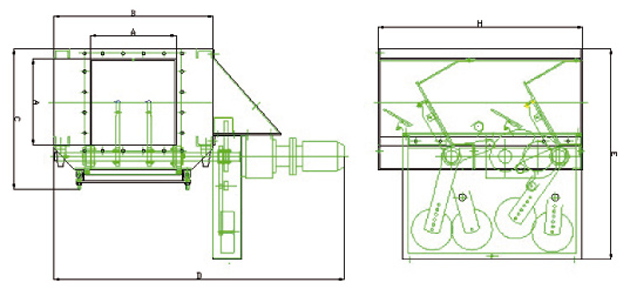

Double-flaps valves – dimensions :

| Type / Diameter | A (mm) | B | C | D | H | E |

| 200 | 210 | 540 | 450 | 1086 | 560 | 634 |

| 250 | 270 | 590 | 500 | 1100 | 630 | 700 |

| 315 | 336 | 696 | 595 | 1261 | 820 | 900 |

| 400 | 420 | 780 | 684 | 1374 | 1000 | 1029 |

| 400SR | 420×650 | 1010 | 684 | 1708 | 1000 | 1029 |

| 500 | 524 | 884 | 834 | 1606 | 1200 | 1302 |

Characteristics and flow rates are given for information only.

Flow may be variable due to the nature of product and speed of rotation.